Centrifugal Casting

Centrifugal castings are produced by pouring molten metal into a mold that is being rotated or revolved. Molten metal is poured into the spinning mold cavity and the metal is held against the wall of the mold by centrifugal force. The speed of the rotation and metal pouring rate vary with the alloy and size and shape being cast.

The uniformity and density of centrifugal castings approaches that or wought material, with the added advantage that the mechanical properties are nearly equal in all directions. Most alloys can be cast successfully by the centrifugal process.

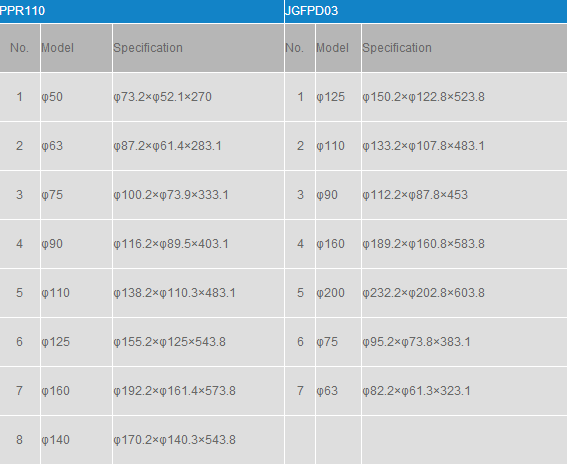

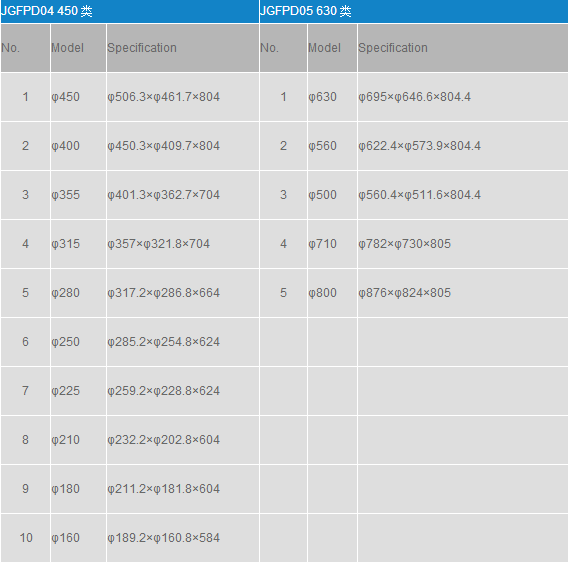

We supply the standard and complex contoured shapes as a single item or in high volume quantities in a broad range of copper, nickel, cobalt, iron and aluminum based alloys. We can supply the max diameter is 1600mm , the max weight is 2000kg each part